RESULTS

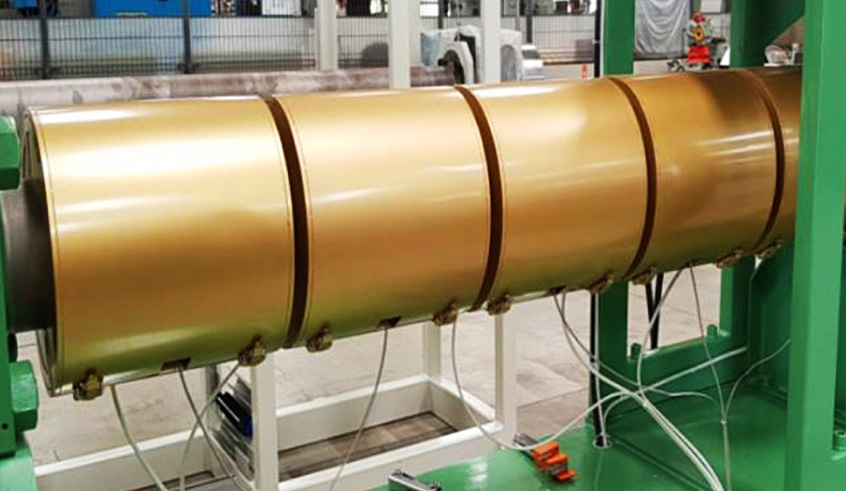

In responding to our good Indonesia client’s request, the traditional band heater heating is both power and time- consuming especially during extruder’s warm-up stage, which makes the production uneconomical with the country’s high electricity rates and unstable power supply...

With the special request on high strength profile yarn applied for land protection weaving fabrics, Raihsing has formulated a production line that takes recycled bottle’s crushed chips as raw material, extrudes the yarns with customized spinneret design followed by...

With the continuous rising costs from labours and utility, Raihsing has successfully brought its subsidiary company- K.R. synthetic fiber, a practical solution of high speed monofilament production line, paired with the latest IFRS heating system and automatic reel to reel winder developed...

As discussed with this globally re-known air filter manufacturer, the thicker diameter of typical monofilament can no longer meet the market requirement for weaving the finer filter mesh applied for efficient air cleaning of dust and foreign matters in the highly...

As traditional curtain screen uses single raw material with single extrusion method, resulting in fabrics being too soft or difficult to weave, co- extrusion line is proposed as a solution, which produces bi- component yarn to make for sturdy weaved fabrics; the project...

The technology of coating has been commonly applied since the beginning of plastic industries, including PVC coated iron wire (to avoid steel rust), PVC coated multifilament used for beach chair, sun-sheds, curtains, and weaved tapes… With more and more innovative plastic compounds...

- Let’s Talk About Your Needs -

We take challenges, and we know it requires open discussion and mutual understanding for a project to succeed. If the standard machine lines are not your solution, share with us your thoughts, problems faced, or the target to achieve. Email us on

sales@raihsing.com / zoe_lee@raihsing.com